Seat Belt Buckle Assembly System Valued at $1.5 Million Projected to Increase Production Efficiency for Automotive Industry

Shen Hui International Group Limited, a professional manufacturer of hardware and plastic furniture accessories, has completed a custom assembly and inspection system for automated seat belt assembly for a customer in the automotive industry. The assembly system, which measures 10 meters in length and 3 meters in width, performs a total of 15 processes, including the assembly of 10 components. The system features pallet transfer equipment, 2-axis and 4-axis robots, laser measurement and vision inspection systems, and a bar code scanner that is used to track and log all tests and inspections.

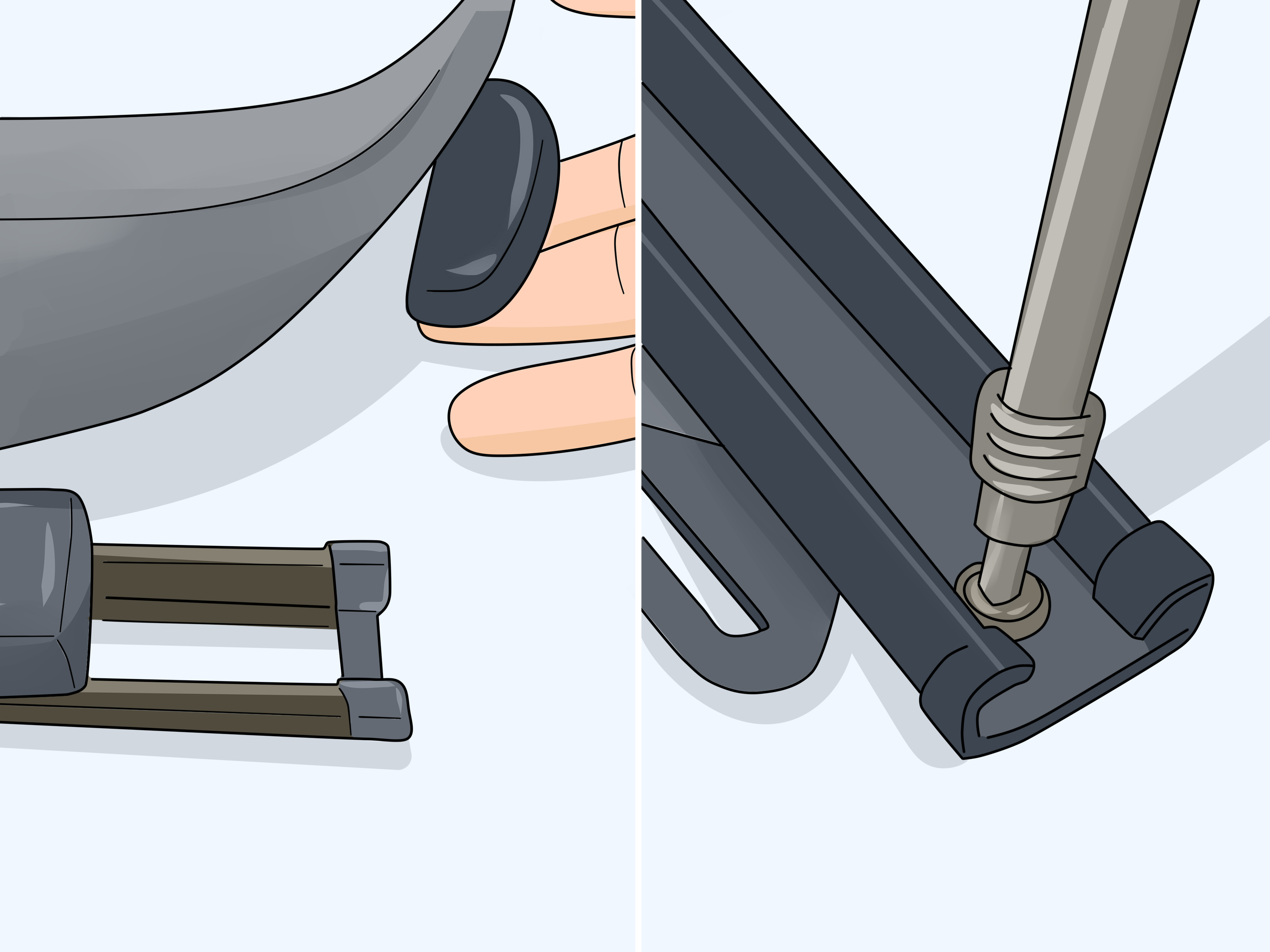

The challenge of the assembly process required automated installation of two different springs and a 2 mm pivot shaft that runs through two components, laser inspection of the servo installed, and rivet height to be held within 0.2 mm to meet the product specifications. To ensure the final assembly was correct, special consideration and a high degree of precision was required from the team at Shen Hui International Group.

All these processes are performed at a record-setting rate of 3.7 seconds per part, increasing production efficiency for the automotive industry.

This project took a total of 24 weeks from development to delivery, and the system will be used for automated seat belt assembly and inspection in the customer's assembly plant located in Windsor, Ontario, Canada. With the completed project, Shen Hui International Group hopes to become an industry leader in customized fabrication, assembly, and inspection equipment offering unprecedented levels of production efficiency.

Shen Hui International Group Limited is located in the Xiqiao Science and Technology Industrial Park, Nanhai, Foshan. It is a professional manufacturer of hardware and plastic furniture accessories, such as multi-function hinges, connectors, sofa feet, and lifts. Shenhui sincerely hopes to become your best partner.

For additional information about the custom assembly equipment project, contact us directly.